Precision Closed Loop Industrial Water Chiller for Hydrogen Energy & Glass Processing Industries

Industrial refrigeration equipment with temperature control is mainly used to provide stable low-temperature cooling media for various industrial production processes. It is particularly suitable for hydrogen production processes that are sensitive to temperature fluctuations and have strict water quality requirements.

Item No :

BS-15WDLOrder(MOQ) :

1Payment :

EXW/FOB/CIF/FCA/DPU/DDUProduct Origin :

CHINAColor :

CustomizableShipping Port :

SHANGHAI/NANJINGLead Time :

15Weight :

690kg

Precise temperature control (-15~35℃) sealed water-cooled chiller is the core cooling equipment for hydrogen production in the glass industry (such as hydrogen production through electrolysis). It can stably control the temperatures of key components such as electrolytic cells and rectifier cabinets, ensuring the efficiency and safety of hydrogen production. The temperature control accuracy can reach ±0.1 to ±0.5℃, and it is suitable for the continuous and high-purity hydrogen production requirements of the glass industry.

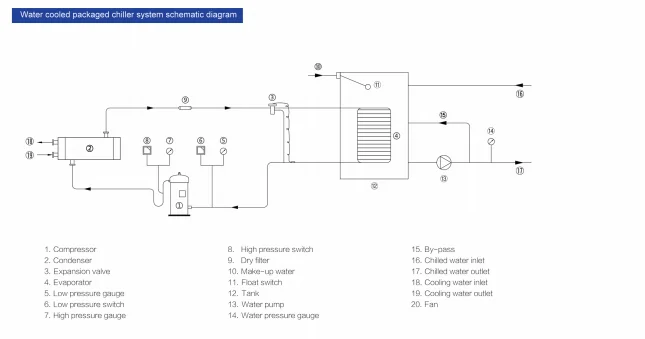

Water cooled packaged chiller Working Principle

Compression: The compressor compresses the low-temperature, low-pressure gaseous refrigerant into a high-temperature, high-pressure gas, providing the driving force for heat transfer.

Condensation: The high-temperature, high-pressure refrigerant enters the condenser, where it exchanges heat with external cooling water (dissipated via a cooling tower) and condenses into a high-pressure liquid.

Throttling: The liquid refrigerant passes through an expansion valve to reduce pressure and temperature, forming a low-temperature, low-pressure gas-liquid mixture.

Evaporation: The low-temperature mixture enters the evaporator and absorbs heat from the closed-loop circulating water, cooling the water down to temperatures as low as -15°C. The refrigerant then evaporates back into a gas and returns to the compressor to repeat the cycle.

Closed-Loop Circulation: The chilled water circulates within a sealed pipeline, exchanging heat only with the evaporator and the load equipment without contacting the outside air. This ensures clean water quality and stable system operation.

Safety Protection Function

Precise Temperature Control and Wide-Range Adjustment

The temperature control range of -15~35℃ meets the temperature requirements of different hydrogen production processes, such as low-temperature condensation and normal-temperature equipment cooling.

Equipped with a PID intelligent control system and PT100 high-precision sensors, the temperature control accuracy can reach ±0.1~±0.5℃, preventing temperature fluctuations from affecting hydrogen production efficiency and product purity.

Closed-Loop Design Ensures Stability and Safety

The circulating water operates in a closed loop, preventing air ingress that could cause oxidation, scaling, and blockage, thereby extending the service life of pipes and equipment. It is particularly suitable for the high-cleanliness and low-maintenance requirements of the glass industry.

This design avoids water evaporation and contamination, reduces water replenishment frequency and water treatment costs, and prevents potential safety hazards caused by the mixing of hydrogen and air.

High Efficiency, Energy Saving, and Stable Heat Dissipation

The water-cooled method offers much higher heat transfer efficiency than air-cooled systems, making it suitable for the continuous, high-power operation of hydrogen production in the glass industry, with a higher comprehensive energy efficiency ratio (COP).

It can be equipped with an inverter compressor and a heat recovery module to dynamically adjust according to heat load, saving more than 30% energy and meeting the “dual carbon” requirements.

Safety Protection and Intelligent Operation & Maintenance

It features multiple protection functions such as high/low pressure protection, overload protection, water cutoff protection, and temperature abnormality alarm, preventing equipment failures and safety accidents.

Support for communication protocols such as Modbus-485 enables remote monitoring and automatic data recording, suitable for the automated management of glass factories.

FAQ

Q1: What are the main components of the water chiller?

A1: The main components include the compressor, condenser, evaporator, expansion valve, water pump, water tank, and control system, etc.

Q2: What is the temperature range and precision of your machines?

A2: We provide solutions covering -80°C to +350°C, with temperature control precision up to ±0.5°C, depending on the model.

Q3: What industries are your temperature control systems used in?

A3: Our equipment is widely used in plastic molding, die-casting, chemical processing, pharmaceutical, printing, and electronic manufacturing. If you share your process details, we’ll match the most suitable model for you.

Model And Technical Parameter

| Model | Unit | 03WS | 05WS | 08WS | 10WD | 12WS | 15WD |

| Temp. control range | Inlet water temperature 7-25℃ | ||||||

| Temp. accuracy | PID±1℃ | ||||||

| Power | AC3Φ380V 50HZ 3P+E(5M) | ||||||

| Heat transfer medium | Water | ||||||

| Cooling methad | Indirect cooling | ||||||

| Refrigeration capacity | KW | 9.2 | 15.3 | 24.6 | 32.5 | 37.6 | 48.5 |

| Pump power | HP | 0.5 | 1 | 2 | 3 | 5 | 7.5 |

| Max.pump flow | L/min | 95 | 165 | 236 | 315 | 385 | 415 |

| Max.pump pressure | Bar | 2 | 2.2 | 2.4 | 2.6 | 2.8 | 3 |

| Pump Power | KW | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| Evaporator(Water Flow) | m³/h | 2 | 3 | 5 | 6 | 7 | 9 |

| Tank Volume | L | 55 | 75 | 150 | 150 | 150 | 200 |

| Dimension(mm) | L | 900 | 900 | 1300 | 1300 | 1450 | 1450 |

| W | 650 | 650 | 800 | 800 | 900 | 900 | |

| H | 1300 | 1300 | 1500 | 1500 | 1550 | 1550 | |

| Weight | kg | 150 | 220 | 310 | 360 | 450 | 650 |

Note: The specification is subject to change due to product improvement without prior notice.

Process Flow Diagram

Application Case

Our oil temperature control unit is widely used across various industrial applications, including casting moulds, rubber vulcanization, wheel temperature control, hot press technology, carbon fiber production, and chemical reactions. It ensures precise temperature management, improving production efficiency and product quality in these processes.

Our Partner

Customized Solutions for Your Business, Contact Us Quickly!

Leave A Message

Scan to Wechat/Whatsapp :